In a project we carried out in 2007, it was planned to make sun roof modifications to 4×4 off-road vehicles.

In project planning, we suggested that we should create a model that would be closest to the sunroof system, design work would be done on this model and we would put the new product into mass production accordingly.

3d Measurement

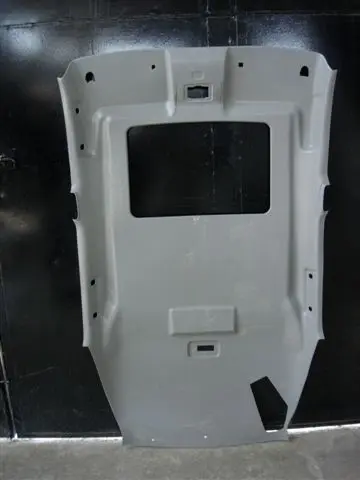

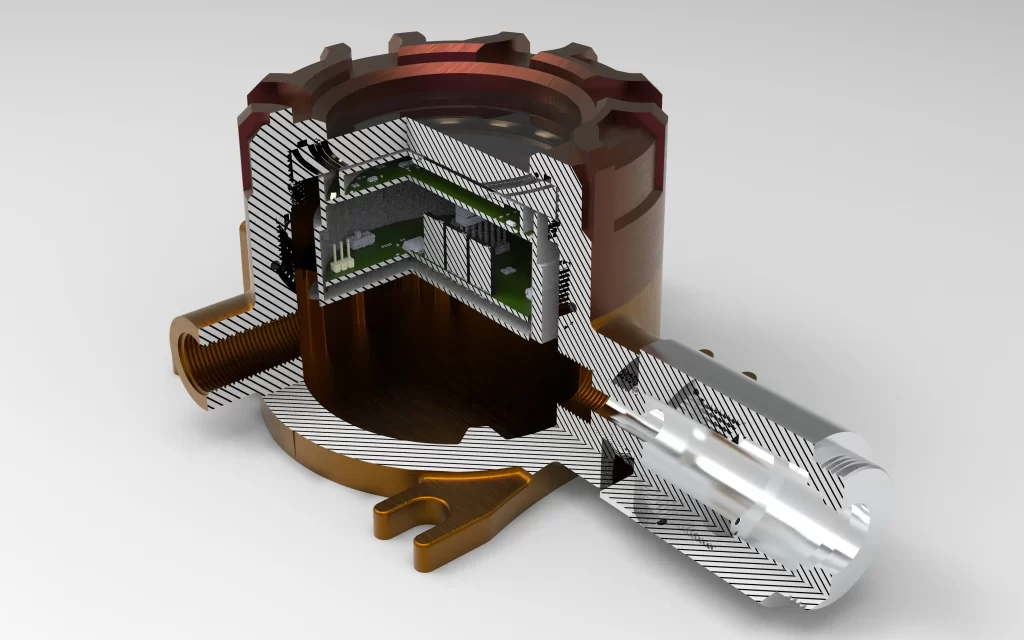

The existing ceiling covering on the vehicle was removed and the sun roof was installed. The ceiling covering, cut to suit the sun roof, was installed. 3D measurements were made using the 3D scanning method to carry out design work based on this model. In order to take precise measurements in narrow areas, special equipment was provided to enable the 3D measurement system to move within the vehicle, and some of them were made. In addition, systems called photogrometry were also used in the project to ensure accuracy in measurements. The 3D measurements taken were transferred to the computer in STL format, indicating all surface and boundary lines.

Re-design – Reverse Engineering

The forms, whose 3D measurements were taken, were modeled faithfully to the existing design and connection points of the vehicle, thanks to the advanced surface capabilities of the CATIA software. The redesign work is also called reverse engineering. In our reverse engineering studies; In addition to modeling the existing product exactly, the model applied to the modified vehicle, as in this project, is also improved and its lines are designed to be complete and precise. The redesigned ceiling was produced using wooden molds and the vacuum method.

The new ceiling produced was installed flawlessly and precisely in accordance with its original state, as seen in the photographs below.

.