Design and Rapid Prototype

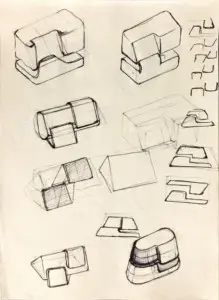

Defne Engineering cooperates with universities in joint training. İrem KAYA and Yaren ULUG, our industrial product design students at Joint Education, carried out concept development studies on passive sound amplifiers.

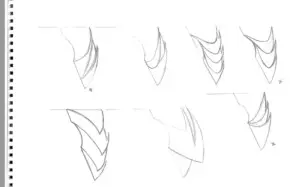

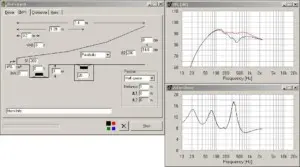

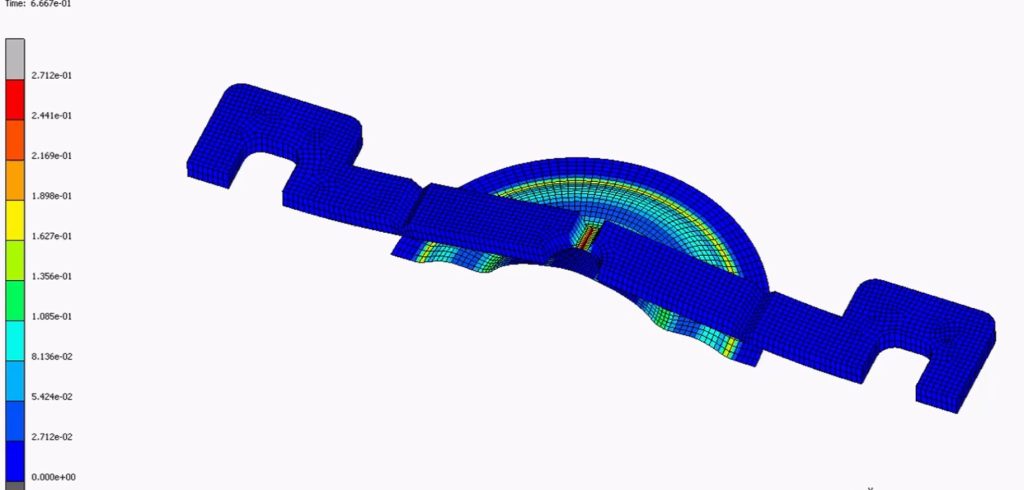

They created a vocal tract concept using different geometries to suit pop and rock sound profiles. Using acoustic analysis software for the sound path, they focused on a few geometries that would increase the sound amplifying feature but would not change the sound frequency.

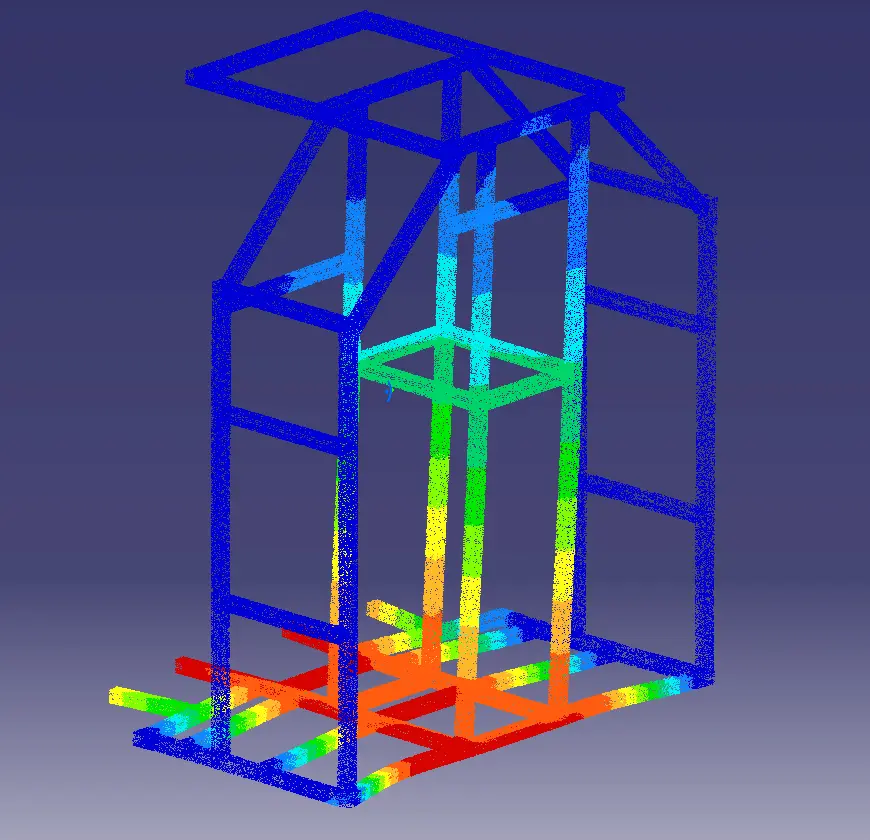

To find the best sound frequency match, they prepared their design in 3D using acoustic vocal tract analysis software. Acoustic sound path alternatives were produced and tested using the rapid prototype production method. After the test studies, the two models that gave the best results were produced as prototypes using the layered manufacturing method. The designs were planned to be produced by the layered manufacturing method, using new technology that would not be particularly suitable for mass production. Additive manufacturing technology called FDM method was chosen. In this method, molten plastic is poured from one or two units to form each layer in a way that follows 2-dimensional contours. After one layer is completed, the plate moves for the next layer, creating the product in the third dimension. This principle is approximately the same in all rapid prototyping methods. Each layer is produced and another layer is added above or below it. Similar technologies that use light, powder, filament, liquid, plastic, wood, metal and even sand use this principle of additive manufacturing.

The resulting products are subjected to subsequent processes and obtain their final shape and strength using certain technologies. Additional post-processes such as surface treatments, painting and coating are applied to the products that have their final geometric and mechanical properties and are made ready for delivery to the end user. In this study, prototype products exhibit the performances shown in the video below after assembly and painting.

In order for everyone to benefit from our design; You can download the data in STL format from this link on our website so that rapid prototypes can be produced.

Saygılarımızla