The Power of Modern Technologies in Reverse Engineering & Product Development

In today’s industrial landscape, reverse engineering has become an indispensable discipline for understanding, improving, or recreating the design and functionality of existing products. Thanks to advanced technologies such as 3D scanning and laser scanning, this process is now more precise, faster, and more reliable than ever before. This article explores how these technologies are transforming modern product development.

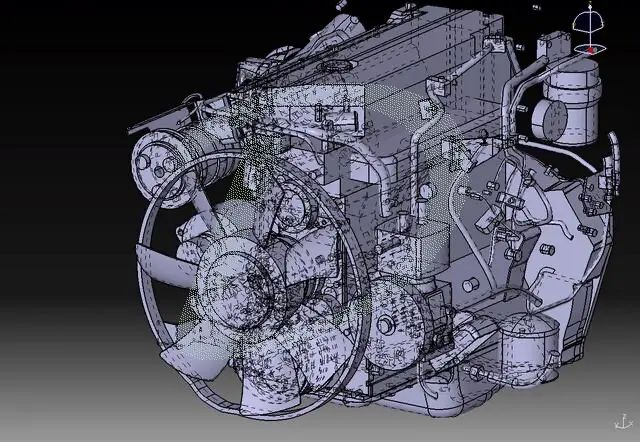

The Cornerstone of Reverse Engineering: 3D Scanning

The first and most critical step in any reverse engineering project is transferring the physical object into the digital world with flawless accuracy. This is where 3D scanning becomes essential.

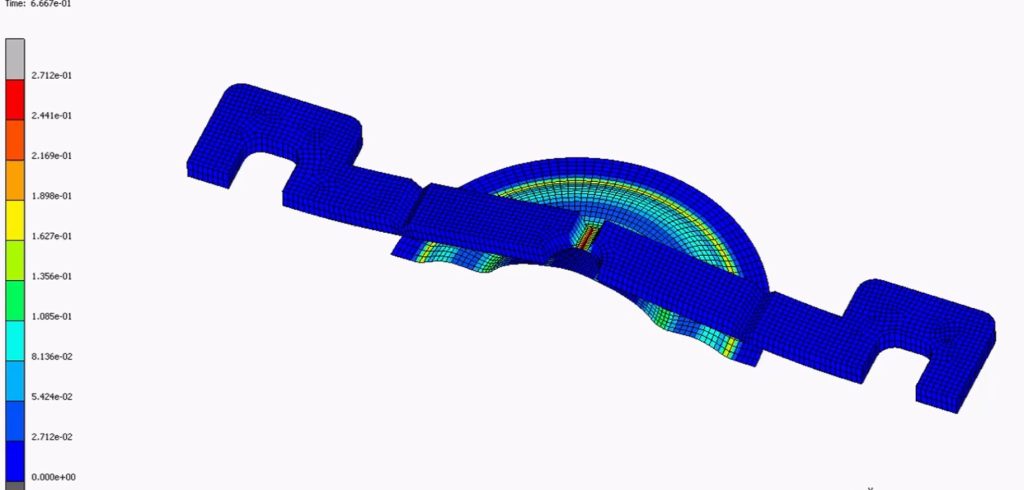

Measurements that would traditionally take days—or even weeks—can now be completed within minutes using a 3D scanning device. By projecting structured light or laser beams onto the surface of an object, the device captures millions of data points, generating a detailed point cloud. This point cloud forms the foundation of the object’s digital twin.

Capable of capturing complex geometries and freeform surfaces, 3D scanning dramatically reduces the time required to understand the design and is an irreplaceable tool in reverse engineering workflows.

Precision Redefined: Optical Scanning & Laser Scanning

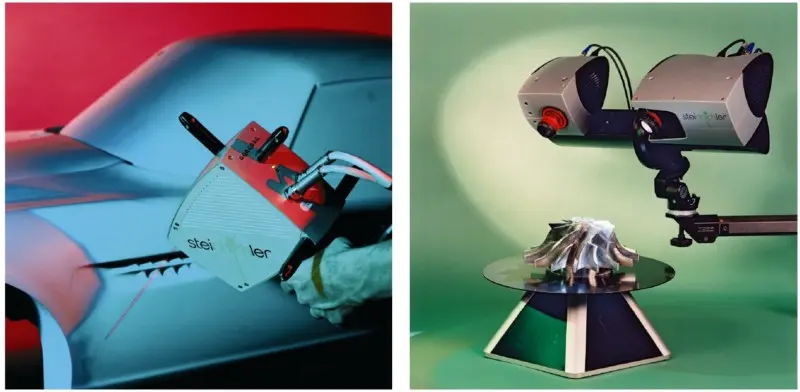

Optical and laser scanning represent high-precision forms of 3D scanning. These systems operate with micron-level accuracy, capturing even the smallest surface nuances.

This degree of precision is critical for reverse engineering in industries such as aerospace, automotive, and medical devices, where even slight deviations can impact performance and safety.

A powerful and precise optical/laser scanning system eliminates bottlenecks during data acquisition and has become an integral part of modern quality-control processes. For this reason, advanced optical and laser scanning equipment is now considered essential in any high-tech engineering environment.

Workflow Integration & Product Development

Reverse engineering is not merely a duplication tool; it is a powerful mechanism for innovation and product development.

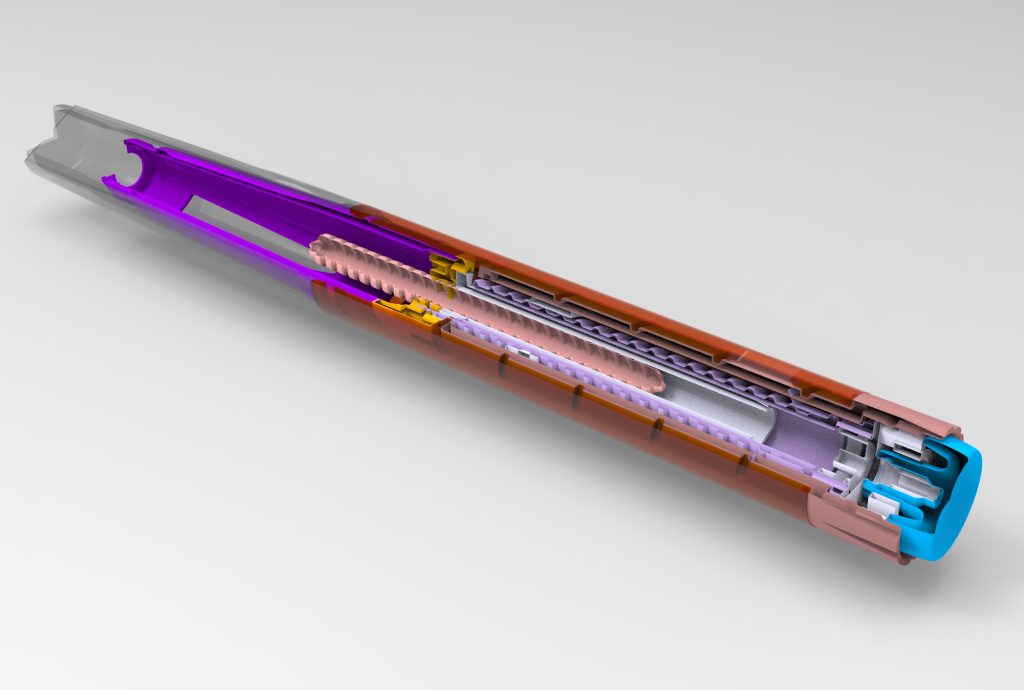

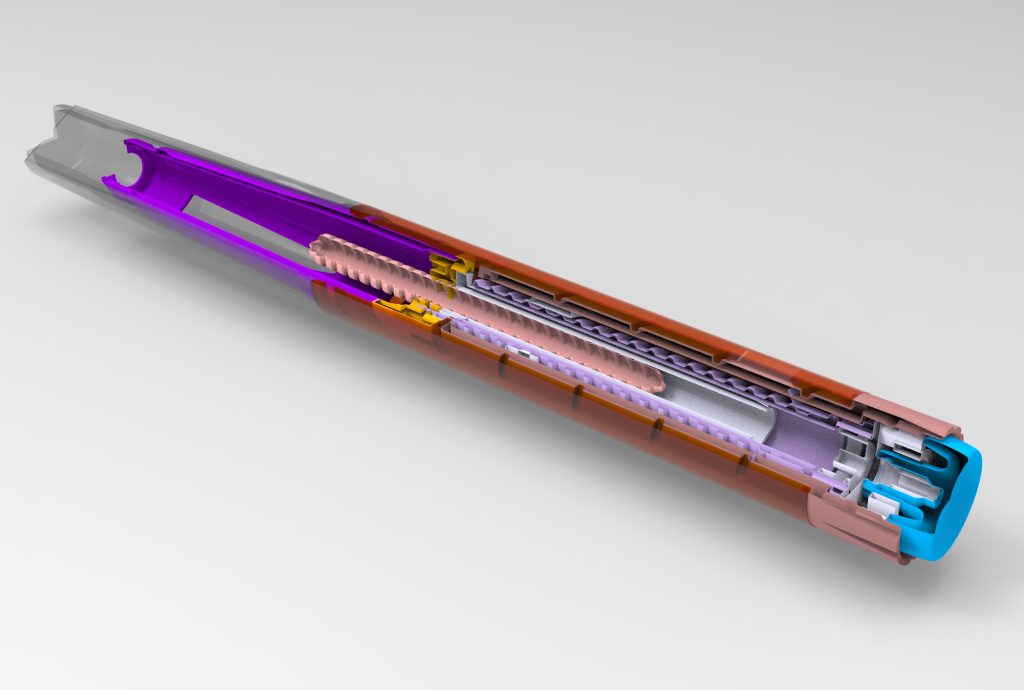

Digital data obtained through 3D and laser scanning is processed in CAD environments, allowing engineers to improve existing designs, customize features, or create entirely new products. For instance:

- A successful market product can be analyzed through reverse engineering

- Its 3D scan data can be studied to identify opportunities for performance enhancement

- Components can be redesigned to reduce manufacturing costs or improve durability

This represents the essence of strategic product development. Today, a competitive product development process requires the integration of these digital tools at its core.

Our Approach

Reverse engineering has reached a new dimension thanks to the speed and accuracy provided by 3D scanning and laser scanning technologies. These tools allow engineers and designers to digitize the physical world flawlessly and innovate freely within digital environments.

Whether the goal is to streamline the production of an existing component or analyze a competitor’s product to design a superior alternative, these technologies form the backbone of intelligent product development. A well-structured approach to reverse engineering and product development positions companies one step ahead of the competition.