Industrial Product Design & Product Development – Professional and Sector-Focused Solutions

Industrial Product Design

What is industrial product design?

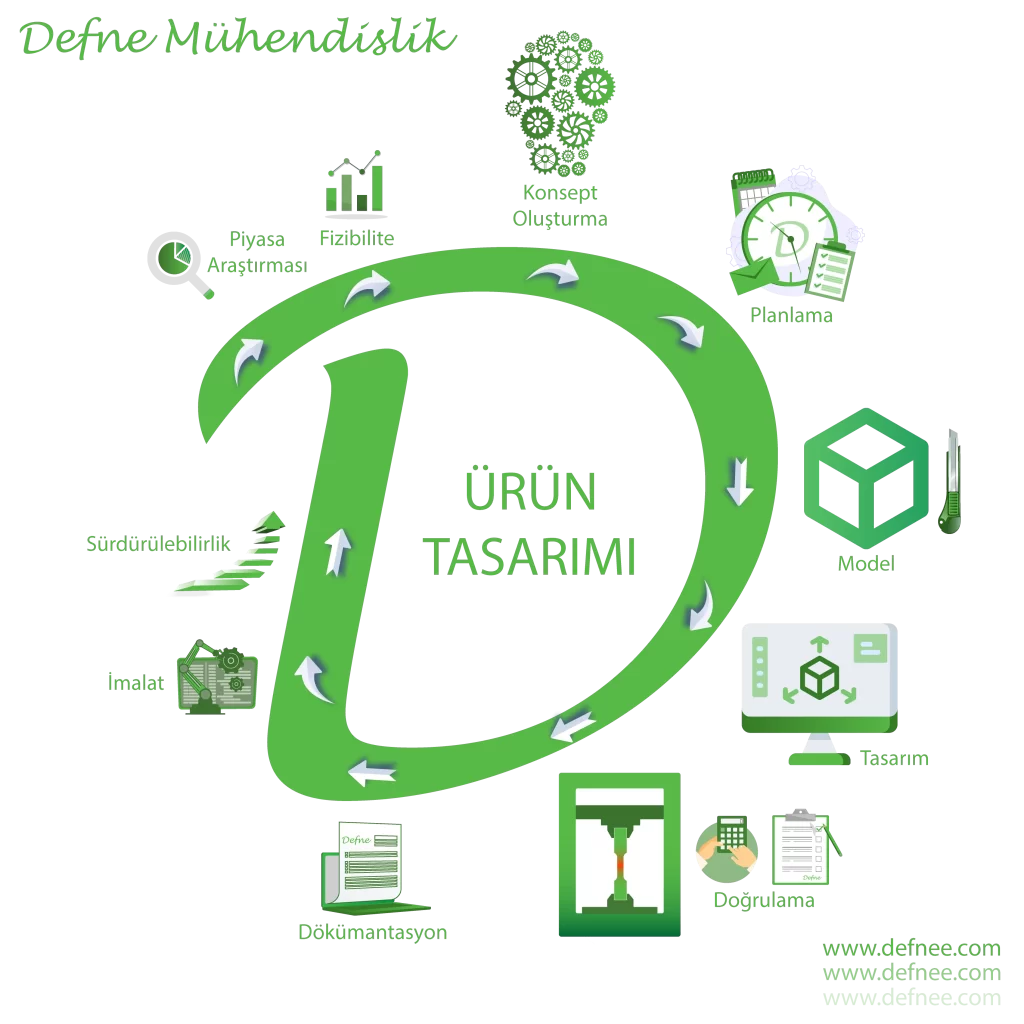

Industrial product design is a comprehensive development process that covers a product’s aesthetic form, functionality, ergonomics, manufacturability, durability, and sustainability. At Defne Engineering, we provide turnkey product development services, managing every stage from initial concept to mass production.

This approach enables brands to enter the market with faster, more reliable, and more competitive products.

Why Defne Engineering? — Our Value Proposition

Defne Engineering offers concept design, mechanical design, 3D modeling, prototyping, testing & validation, and mass-production preparation under one roof. Each product is tested according to its use-case, while maintenance, serviceability, recyclability, and production costs are strategically planned during the design phase.

Industry-Specific Professional Product Design Services

▶ Medical Product Design & Development

- Biocompatible material selection

- Sterilization-compliant design

- Compliance with medical device safety standards (ISO, IEC)

- Ergonomic usability and clinical durability

Medical product design, medical device development, biocompatible design, sterilization testing

▶ Defense & Aerospace System Design

- Vibration and impact resistance analyses

- Compliance with military standards (MIL-STD)

- Engineering for demanding environmental conditions

Defense industry product design, MIL-STD testing, durability analysis, military technology development

▶ Consumer Electronics Design

- Thermal management and passive cooling

- EMC/EMI compliance

- Compact, user-oriented product design

Electronic product design, EMC compliance, compact design, consumer electronics development

▶ Industrial Machinery Design

- Mechanical load and durability analyses

- IP protection rating design

- Easy maintenance and serviceability

Industrial machinery design, mechanical engineering, IP protection design, industrial equipment development

▶ Home Appliances & White Goods Design

- Cost optimization

- Ergonomic user experience

- Moldability and mass-production feasibility

White goods design, mass-production design, user experience, design engineering

▶ Energy Systems & Renewable Energy Products

- Outdoor-ready structural durability

- Long-life component engineering

- Sustainable material selection

Energy system product design, renewable energy product design, durability engineering

End-to-End Development: From Concept to Prototype and Mass Production

The Defne Engineering product development process includes:

- Industrial design and concept development

- 3D CAD modeling

- Mechanical design and engineering analyses

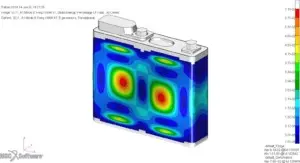

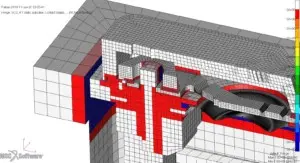

- FEM/FEA/CFD simulations

- Functional and aesthetic prototyping

- Testing & validation

- Production preparation and technical documentation

Product development process, mechanical design, prototyping, mass-production readiness

Product Lifecycle Management (Maintenance – Repair – Recycling)

Our design methodology covers the entire product lifecycle:

- Easy maintenance and repair

- Field serviceability

- Spare part planning

- Recyclable material selection

- Sustainable design principles

Sustainable product design, recycling-oriented design, product lifecycle management

Result: Competitive, Reliable, and Production-Ready Products

Defne Engineering empowers brands with innovative, user-centric, manufacturable, and sustainable product solutions across all industrial product design and development processes.

Industrial product design, product development, engineering design, manufacturability analysis, design engineering

The lifespan of existing or newly released products of product supply companies is much shorter than in previous years. Competitive pressure of the global market; It requires high quality and rapid launch of new and creative products. The more new products contain innovative and creative ideas, the higher the competitive performance of those products and the longer they last. Our company’s industrial product design strategy is based on value engineering, backward engineering and lean principles.

Industrial product design work is the development of the product starting from concept design, creation of detailed mechanical design, and realization of designs suitable for mass production. Moldable designs suitable for the production methods of plastic, metal and different materials are first tested through prototype production and function and field tests, ensuring that error-free, fast and high-quality products are brought to the market.

In the 2020s, the life cycle of creating a new product, its development, sustainability, manufacturing, launch, recycling; It is much different and faster compared to previous periods due to purchasing behaviors and customer approaches. What are Product Design, Product Development and New Product Development, which will form the basis of new projects of manufacturing and trading companies? What are the Product Design Stages? Let’s take a brief look.

What is Product Design?

Product design as a verb is to create a new product to be sold by a business to its customers. It is the generation and development of a wide range of coefficient and impact ideas through a process that leads to new products. Therefore, it is an important aspect of new product development. (1)

Product design as a noun: the set of features of a work consisting of discrete features of form (i.e., the aesthetics of the tangible good or service) and function (i.e., its capabilities) together with holistic features of integrated form and function.(2)

The purpose of product design is to direct and create consumer demands in targeted markets and to have a high market share in a competitive position. The aim should be to create high-tech products equipped with innovative and creative features.

If product design is considered in a broad sense within the scope below, it is possible to create or expand a sustainable brand/product. These studies should be handled as a project with the coordination of designers, marketing experts, engineers, production and maintenance teams. (3) (4)

What are the Product Design Stages?

Product design studies; It consists of Market Research, Feasibility, Concept Creation, Planning, Model Production, Mechanical Design, Verification, Documentation, Manufacturing and Sustainability stages. (5)

Market Research

Listing of possible competing products in the targeted market, their market positions, production methods, costs and profitability estimates are created. A prediction of what the new trends will be and their location should be provided. This information will be used as data for conceptual design and feasibility studies.

Feasibility

At this stage, where the general picture of the investment is created, such as design and development processes, manufacturing methods, targets, production materials, workmanship, marketing supply and sales channels, cost analyses, mechanical values that will be taken as basis in concept studies are created. (6)

Concept Creation

Concept design is the first big picture. It is a study aimed at creating or directing consumer demands. This is the stage where strategies begin to take physical form. Creative and innovative contributions and even concepts created with a methodical approach such as TRIZ enable the creation of leading products in their field. Concept design is the creation of product details using the results of market research and feasibility studies. The entire infrastructure of the product, such as ergonomics, visuality, function, mechanical details, material, color, production and maintenance, that will be effective throughout its life, begins to take shape at this stage. (7)

Planning

The roadmap of which problems of the product we will solve and how we will solve them is determined at this stage. Details of studies such as Design, Validation, Documentation, Procurement, Production, Maintenance, Repair, Spare parts, Recycling, Improvements are created.

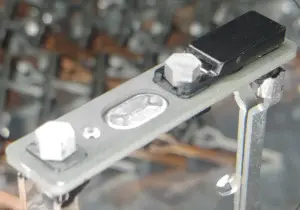

Model Production

Concept design is the visual creation of form features such as volume and aesthetic ergonomics of the completed product. The clay model, the foam blocks, are the first visual physical product produced by 3D printers – the prototype. It is used in customer experience, user approach and ergonomic suitability studies.

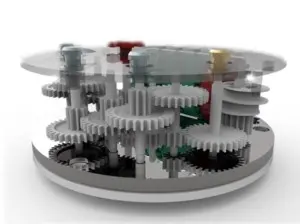

Mechanical Design

It is a computer-aided design work to create the mechanisms of the product, whose outlines have been determined with the concept design, in a way that best suits the production, assembly and maintenance conditions, with all its sub-parts. In order for the product to fulfill its function, its durability and compliance with working conditions and standards are taken into consideration. Verification studies are also carried out for critical values. In this study, material, production and assembly tolerances, quality requirements and packaging details and features are established.

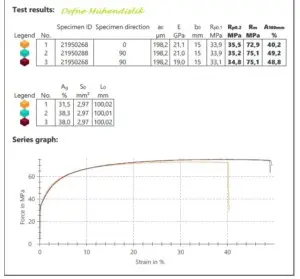

Verification

These are the studies carried out to determine and approve the working and environmental conditions of the product created as a result of mechanical design, and to ensure that its function is fully fulfilled. In these studies, the product is produced as a prototype for use and testing in the field. Prototype production is carried out from real material in accordance with the dimensions and tolerances. Depending on the place of use and purpose, similar materials and methods can also be preferred. Again, depending on the place and purpose of use, physical and/or simulation testing of the product is also a verification study. Thus, it is confirmed that the mechanical design will achieve its lifespan and function. Optimization of the product is carried out according to the results of the verifications. After the design is clarified, packaging and packaging designs are also verified. At this stage, certification standardization preliminary studies begin.

Documentation

Certifications and technical documents that the product must obtain according to its intended use are prepared. Necessary documents such as technical drawings, bill of materials, manufacturing procedures, patent applications and permits are created after the design is finalized.

Production

Depending on the purpose and use of the product, pre-production, first sample control (FAI), assembly and control fixtures, tooling, packaging and packaging details are completed with the selected production method. Test apparatus arising from the quality requirements of the supplied products and the parts produced are also finalized and produced at this stage. Necessary production adjustments are made by reviewing the tolerances and tolerance stack analysis results taken into account during the design phase.. (8)

Sustainability

It is the carrying out of stages such as development, improvement, optimization, cost reduction, and ensuring competitive continuity that will take place throughout the life of the product. These are the development efforts carried out to ensure that the product remains up-to-date and maintains the highest market share throughout its market life.

The designs of products that have a high market share, that can maintain this share, and that can lead their competitors must be designed by teams that are experienced, constantly improving themselves, open to new ideas and knowledgeable about high technology, and follow their projects to the end. (9)

Defne Mühendislik we carry out high quality, fast projects with the principle of continuous development.

References on the subject

- https://en.wikipedia.org/wiki/Product_design

- Luchs, M., & Swan, K. S. (2011). Perspective: The Emergence of Product Design as a Field of Marketing Inquiry. Journal of Product Innovations Management, 28(3), 327-345. doi:10.1111/j.1540-5885.2011.00801.x

- Sustainability ISSN 2071- 1050www.mdpi.com/journal/sustainability

- Quick Guide to Sustainable Design Strategies. Leyla Acaroğlu

- ISO 9001:2015 Bölüm 8.3

- Feasibility Studies in the Product Development Process Katharina Bause et al. / Procedia CIRP 21 ( 2014 ) 473 – 478

- https://tr.wikipedia.org/wiki/TRIZ_yaratıcı_problem_çözme_

- Zhang, C.(., Wang, HP.(. Robust design of assembly and machining tolerance allocations. IIE Transactions 30, 17–29 (1997). https://doi.org/10.1023/A:1007437427523

- https://newschoolarch.edu/blog/what-is-product-design https://engineering.purdue.edu/productdesign/wp/