Testing and Verification Structural Analysis Design Validation with Prototype

In Product Design and Development projects, we carry out features such as approval and verification of designs, function tests under working conditions, behavior and ergonomic suitability through mock-up, prototype and/or computer-aided structural analysis. We call physically produced non-functional parts or groups of parts Mock-up. We call prototype the production process of physical parts that can fulfill their function. In addition to these studies, we verify our designs by calculating the structural behavior of the products, their durability in working environments and even their lifespan with computer-aided analysis programs. Within the real tests required for the certification of the product, prototypes are produced from real materials and the tests are approved. As Defne Engineering, we see our Testing and Validation studies as an indispensable phase of our product design and development projects. That’s why we can keep our customer satisfaction above 97% in our work.

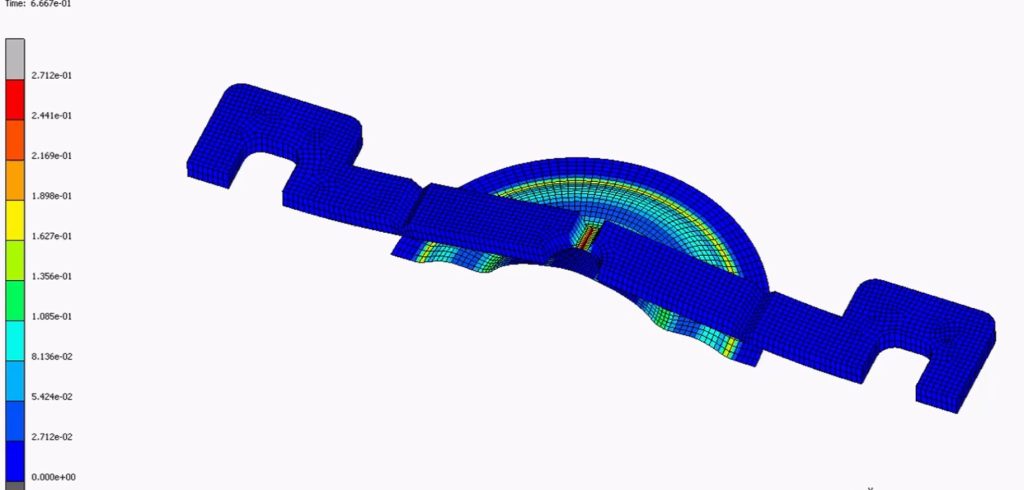

CAE Computer Aided Engineering

In our Product Design studies; We carry out computer-aided analysis studies to ensure that the product can perform its functions throughout its life cycle, to determine the life cycle time and similar engineering calculations. As a result of these analyses, after verifying the behavior of the product in the virtual environment, we ensure the approval of the design by subjecting it to real tests with prototype production.

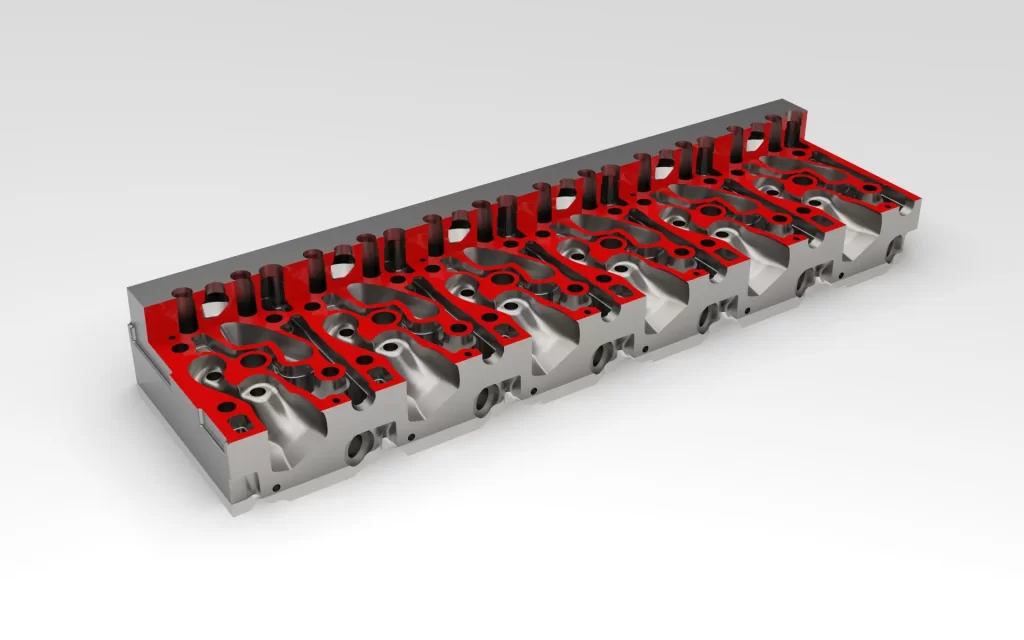

Prototype & Mock-up

The physical parts we call Model (Mock-Up) are models produced to test visual integrity in Product Design, especially in the Concept Development phase. These models are used for different purposes such as ergonomics, marketing, presentation, receiving feedback, and concept approval. Mock-ups are not expected to fulfill the functions of the product. The purpose of prototype production is; It is the verification of the product’s performance of some or all of its functions, the approval of its behavior under usage conditions and, ultimately, the verification of the product design. Prototypes are produced and tested from real materials or the closest material to the real thing using an engineering approach. Producing prototypes close to mass production conditions depends on the effectiveness of the production process in the product.