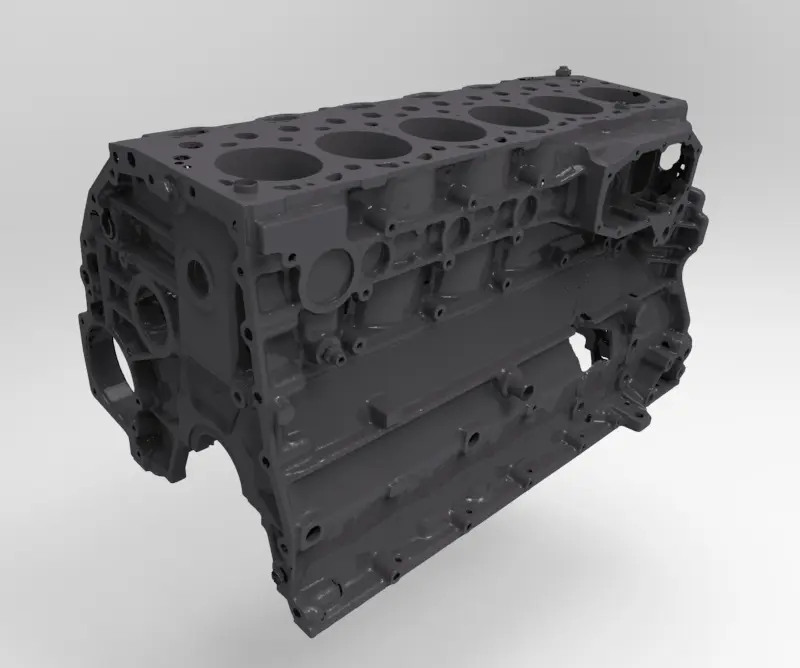

We define product development as the development studies carried out on the design and production-based product for similar purposes such as updating an existing product, reducing its cost, increasing its competitiveness, extending its market life, and comparison-based use. Product development is the creation of a new product with more advanced features by examining existing products on the market. We carry out product development studies using reverse engineering methodology. In studies carried out by applying the reverse engineering methodology, the physical properties of the part, material, strength, production method and the entire infrastructure that forms the identity of the product are examined. You can access our Product Development strategies studies here. Let’s briefly summarize what the Reverse Engineering methodology is.

What is reverse engineering methodology?

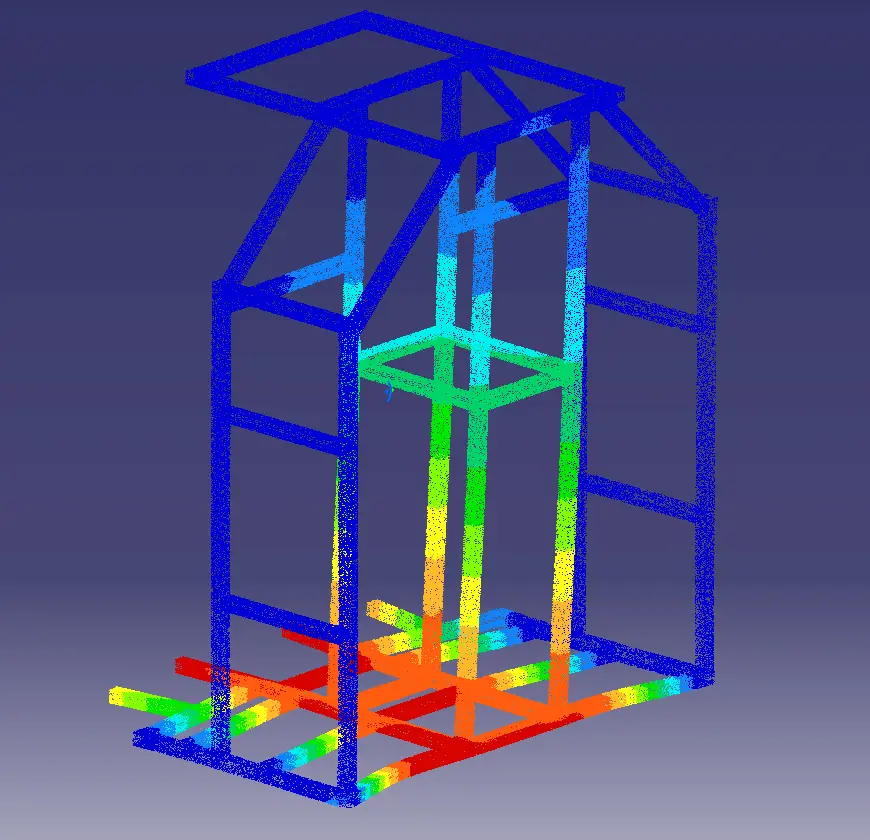

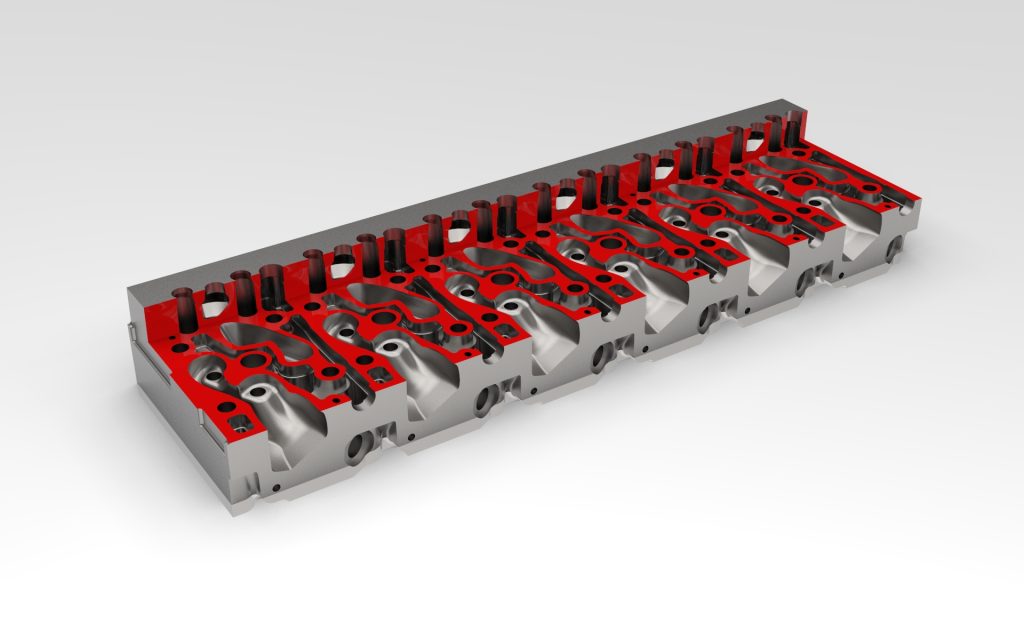

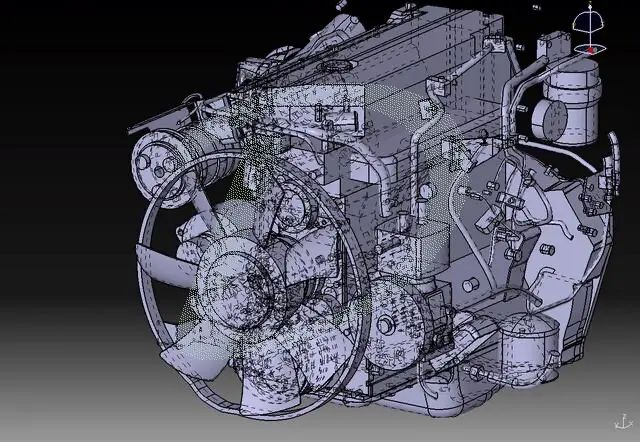

Reverse engineering methodology is used to decipher the physical, mechanical, functional and production methods of the product and/or its sub-parts. Reverse engineering studies are directed and planned in line with the company’s goals. In this way, the details of the examinations and engineering work to be carried out are determined. Defne Engineering, which has carried out more than 100,000 hours of reverse engineering and product development strategies and projects since 2005, carries out much higher quality projects at affordable costs with the experience it has gained. Based on the experience gained by experience, we follow a process that guides, complements and supports its customers in achieving the goals of the projects.

As a result of reverse engineering studies, not only the deficiencies, strengths and weaknesses of the product are determined, but also development opportunities are determined much more clearly. The information obtained also helps in determining which problems will be overcome and how in the development phase. Development opportunities, competitors’ advantages and how to capture new advantages are determined at this stage.

What is product development strategy?

During the product development phase, design studies are carried out in accordance with the production methods determined depending on the target audience and quantity of the product. In design and development studies, products suitable for production that meet user demands are developed.

Suitability of designs for production, establishing tolerances, production method details, and creation of documentation require finely detailed and high-quality work and experience. Carrying out these works by an experienced team makes a great contribution to overcoming possible problems of the product. It is ensured that production starts without any problems the first time.

As Defne Engineering, both reverse engineering and product development studies are followed until the product goes into mass production without any problems. This approach enables us to work together with our customers on every project.