Benchmarking is a critical step in the Product Developmentand Value Engineering processes. Generally, in order for a business to evaluate its own performance, it examines businesses with similar or higher performance and compares the business methods of these businesses with its own. Nowadays, technical features, performances and prices of products are compared. The study defined by Defne Engineering as benchmarking consists of comparing and reporting main issues such as engineering, design, concept, up-to-dateness, production method, maintenance and repair. In comparison, the reference product or products are selected. In this selection, the product to be developed is either taken as a basis or the study is carried out based on the target product. Other products are evaluated according to the reference product. Scoring comparison criteria vary from project to project. The impact values of the criteria are also defined according to the content of the study to be conducted. The parameters of the benchmark are determined from market research and feedback from the sales team. In the comparison study, which will be focused on design and production, criteria such as working conditions, strength and life, as well as the engineering approaches of the products are analyzed.

Competitor, similar or reference products in the benchmarking methodology; It is examined from many different aspects such as physical, functional, material, durability and ergonomics. The strengths, weaknesses, opportunities and threats (SWOT) of these products are analyzed. By using this information during the concept creation phase of new product development projects, high quality development and sustainability of the resulting product is ensured. Generally, the analysis method used in companies’ processes and projects is based on the product. This analysis, which is based on the data of the market analysis, determines the strengths and weaknesses of the product, lists product development opportunities and threats to the life cycle of the product. The aim of this study is to determine the priority issues in development and to determine at what level the development will be implemented.

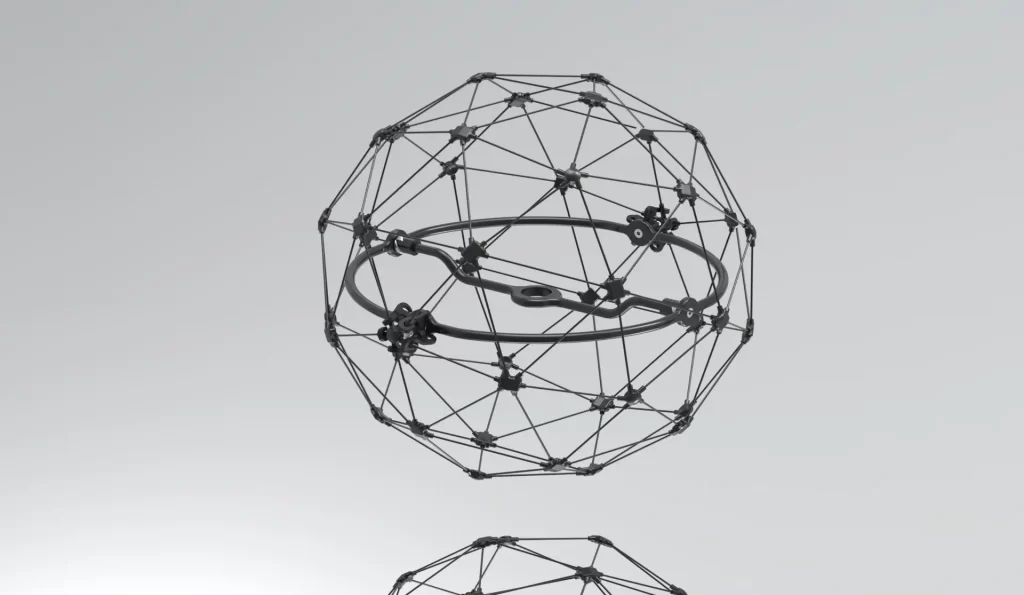

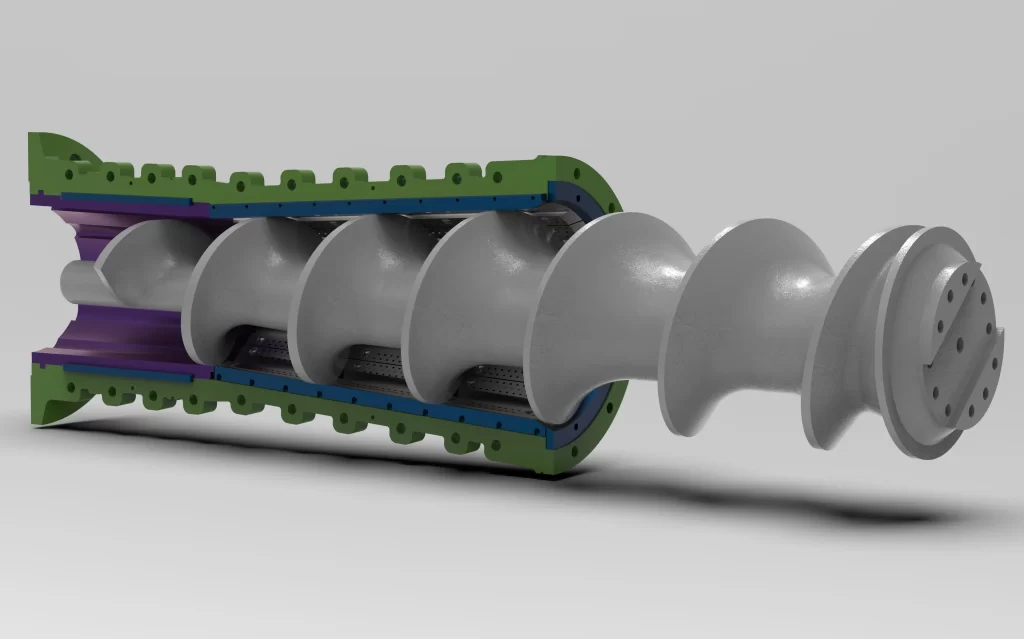

3D Dimensioning, Optical Scanning, Reverse Engineering (Reverse Engineering) processes are used to analyze the differences, advantages and even production methodologies of products and systems relative to each other.

With the contributions of experience and engineering, our company prepares the project development process with a preliminary study comparing the concept design for the new product to be created.