In industrial design and manufacturing, 3D measurement goes far beyond determining dimensions. The two most crucial criteria are precision and detail. For large or complex components, traditional measurement techniques often fail to deliver the required accuracy and completeness.

3D measurement, precision measurement, detailed scanning, optical scanning, laser scanning

Defne Engineering’s Specialized Approach

Defne Engineering evaluates every project according to its purpose, environment, and required accuracy. Technologies used include:

- Photogrammetry systems for measuring large-scale parts

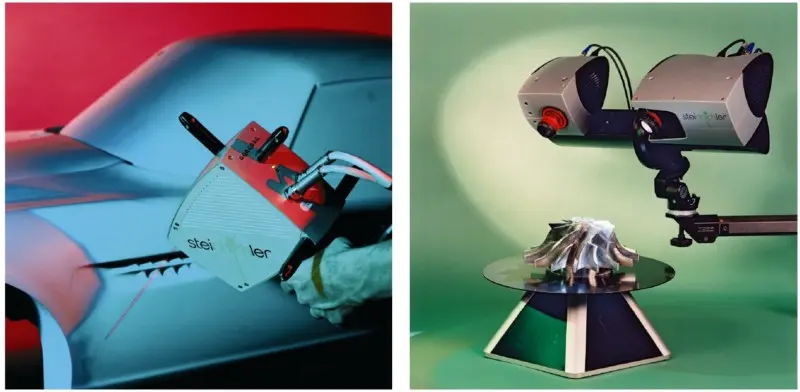

- High-resolution optical and laser scanning equipment

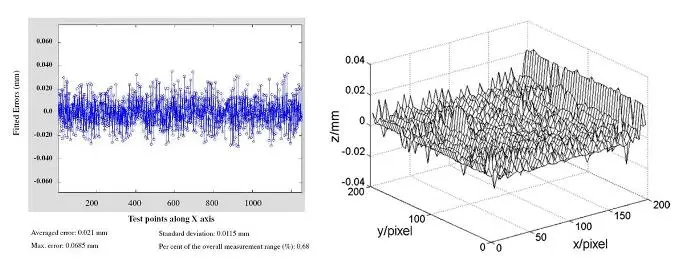

- In-house developed methods and scripts to enhance data accuracy and consistency

With this approach, measurement becomes more than data acquisition—it becomes a reliable input for quality control and reverse engineering processes.

Project-Based Measurement & Purpose-Driven Solutions

Each project is planned individually to ensure maximum accuracy:

- Detailed measurement of large or complex parts

- CAD comparisons to verify manufacturing tolerances

- Point-cloud-based reverse engineering and prototype updates

Industry Applications

Medical & Precision Devices

- Measurement of biocompatible components and sterilization-compatible designs

- High-accuracy scanning of complex medical instruments

Automotive & Defense

- Accuracy verification of molds and prototype components

- Measurement of large, complex mechanical structures

Consumer Electronics & Home Appliances

- CAD validation for compact parts

- Quality-assurance processes prior to mass production

Industrial Machinery & Energy Systems

- Detailed scanning of large, complex industrial components

- Deformation analysis and post-production quality control

3D Measurement for Quality Control & Reverse Engineering

- CAD comparison for validating manufactured parts

- Reverse engineering and prototype development using point-cloud data

- Deformation analysis and tolerance verification for production assurance

Beyond Measurement — Trusted, Actionable Data

Defne Engineering customizes each project and delivers precision data tailored to its purpose. This approach ensures maximum efficiency, reliability, and accuracy across design, manufacturing, and quality-control workflows.

3D measurement, optical scanning, laser scanning, precision measurement, reverse engineering, CAD comparison, quality control