Testing and Validation studies are carried out to ensure the accuracy of the products, parts, molds, apparatus and models that are designed and/or developed. The accuracy of these studies may need to be ensured by different methods depending on the place of use and purpose of the product. This verification is simply done in two main groups. The first is the physical creation of the product. Secondly, it is simulated virtually according to working conditions and material properties.

Physical testing and verification

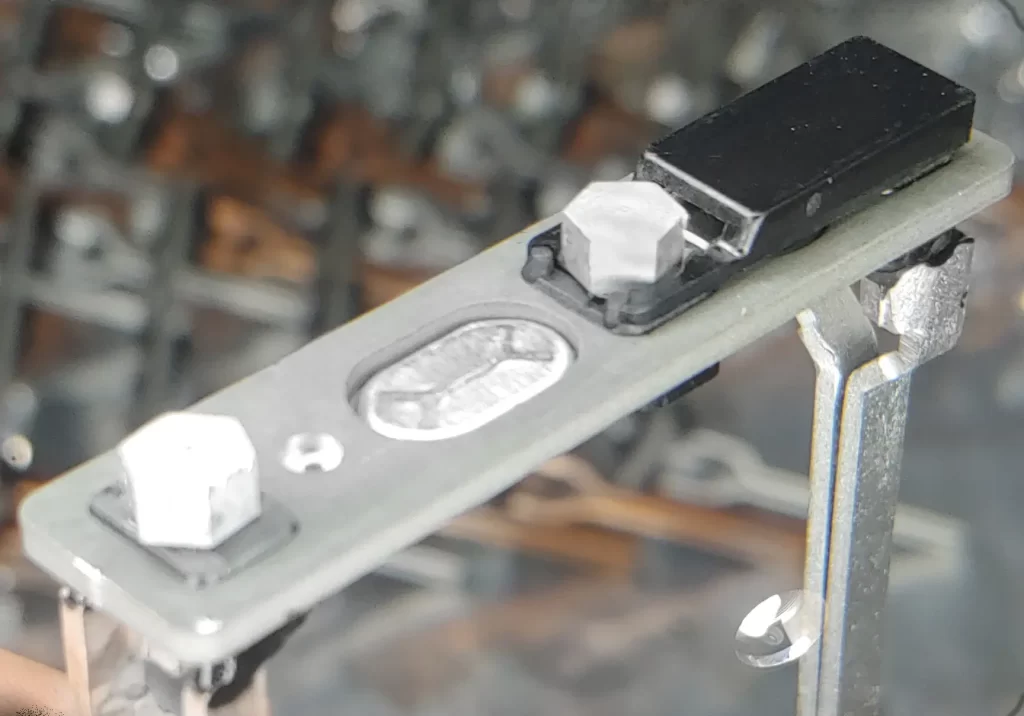

Depending on the working conditions and function of the product to be physically verified, it is produced either by simulation or under real conditions. If it is to be produced by simulation, one of the rapid prototype methods is selected and production is carried out. These technologies are developing very rapidly. The study that best follows technologies and interprets trends is given in the Wohlers Report 2021. (1) Defne Mühendislik we produce plastic and metal-based rapid prototypes with FDM and SAF technologies (2)

- Rapid Prototype

- Small Quantity Production

- Silicone mold

- Quick Mold

In testing and verification, if the product is to be tested under environmental conditions, production by simulation is not sufficient. In this case, we carry out prototypes or pre-production in accordance with the needs using conventional methods such as machining, molded manufacturing, cutting, bending and welding.

What is Simulation?

Simulation or simulation is used in a non-technical sense to mean something similar or fake. In a technical sense, it is the imitation of the operation of a real world process or system over time. It is a model of a system or process that contains defined relationships between system objects. (one)

Simulation is used in many contexts such as simulation of technology for performance optimization, security engineering, testing, education, training, and video games. Often computer experiments are used to study simulation models. Simulation is also used with scientific modeling to take an in-depth look at the workings of natural or human systems. Simulation can be used to show the ultimate real effects of alternative situations and courses of action. Simulation is also used when the real system is inaccessible or dangerous, the application is unacceptable, or systems that have been designed but not yet produced or simply do not exist cannot be implemented. Key considerations in simulation include obtaining valid source information on the selection of important features and behaviors, the use of approximation and simplification of assumptions in simulation, and the accuracy and validity of simulation results. Procedures and protocols for model verification and validation are an ongoing branch of academic study, refinement, research, and development in simulation technology or application, particularly in the field of computer simulation. (3)

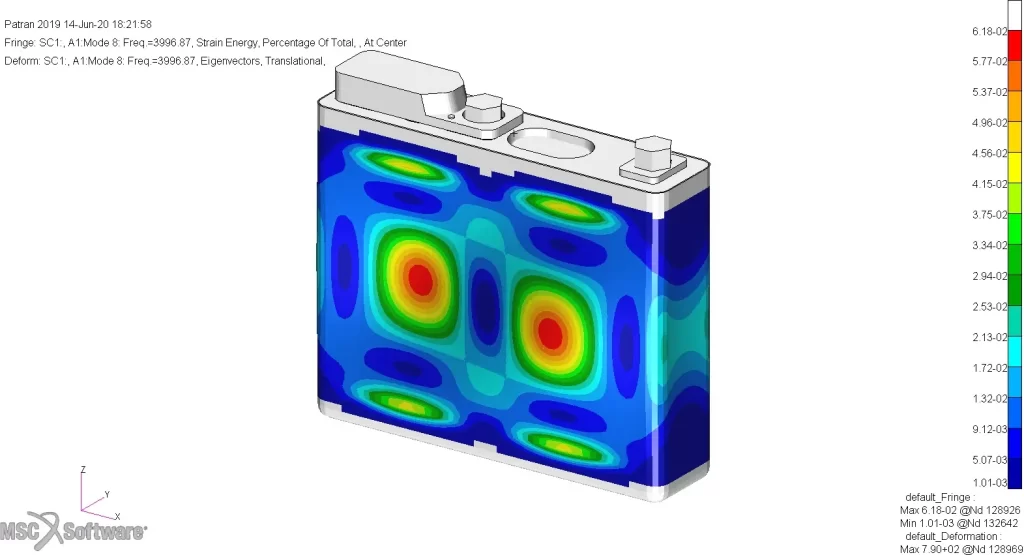

When it is not possible to create and test the operating conditions of the product, linear and nonlinear analyzes are performed with structural analysis software to obtain results on structural issues such as the strength, behavior and life of the product.

Based on this data, optimization, development and tasks of the design are achieved.

In order to ensure complete success in some projects, to achieve rapid success in physical tests and certification, the design has been developed with an accurate simulation and interpretation, and successful results have been achieved in the tests with pre-production made from real materials.

- https://wohlersassociates.com/2021report.htm

- https://www.sciencedirect.com/science/article/abs/pii/S0890695597001375 International Journal of Machine Tools and Manufacture Volume 38, Issues 10–11, October 1998, Pages 1257-1287

- https://tr.wikipedia.org/wiki/Simülasyon