Defne Mühendislik Ltd. Ltd. It is an engineering company that provides product design, product development, 3D Optical Scanning, Retrograde Engineering, Quality Control and Prototype production services. The engineering services it provides throughout the process from the product design phase to mass production enable its customers to offer higher quality, innovative products to the market faster.

The engineering service requested by Sedat Üstündağ construction company for the 40 m tall Atatürk Statue to be built in Buca district of Izmir made our company proud in this regard, and we had the chance to contribute to the Mask (sculpture) of Atatürk, the founder of the Republic of Turkey, to be built in this size. The work to be done was to provide a large-scale engineering structure of a model created by the sculptor.

PROJECT START

The concept determined for the 40 m high Ataturk Mask was chosen as the Ataturk portrait worth over 20 YTL. The sculpture work, created from a clay model made by sculptor Harun Atalayman, was appreciated by the Buca municipal authorities, the owner of the project, and it was decided to continue the project with this work as the basis.

Project; The model, which was finalized by Harun Atalayman, was delivered to Defne Engineering for the purpose of making a copy of the epoxy mold for measurement and engineering studies and transferring this copy to the computer environment by optical scanning method.

Picture 1: Preparation of the mud model by sculptor Harun Atalayman

Picture 2: Model prepared for 3D dimensioning

Defne Engineering started the engineering work of this project with the help of both 3D measurement and the evaluation of the obtained data in accordance with the project purpose and its experiences in mold production, quality control and product development.

The engineering works to be completed in 4 main stages are defined as follows:

- Transferring the form of the model prepared in one meter size to the computer environment,

- Creating data on the computer model to both capture the form and provide the data required for structural analysis,

- Determining the location of the new model with the previously obtained hill data, creating the hill layout plan,

- Depending on the positioning on the hill, the natural rock forms were transferred to the computer environment and the necessary arrangements were made to fill the area around the statue with natural rock,

Stage 1: Transferring the step-by-step model to the computer environment:

The first stage of the plan, which consists of 4 main stages, is the creation of computerized forms of the model. With the experience gained from both automotive and other main industry branches, Defne Engineering transferred the sample taken from the hand-made model to the computer environment with the help of sample fixturing and Breuckmann opto-TOP HE system. The model prepared for measurement was 1 meter in size, and the appropriate camera and field of view were selected, and 3D measurement was made in a way that could capture all the geometric details of the prepared model, but eliminate small errors caused by hand production. As a result of this measurement, the scanning data, which we call point cloud, was prepared in STL format. These data; It will form the basis for other stages such as scaling, form creation, and determination of structural elements from the formed forms.

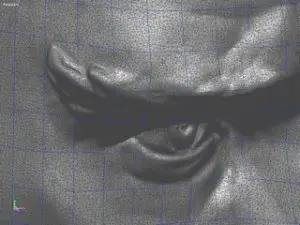

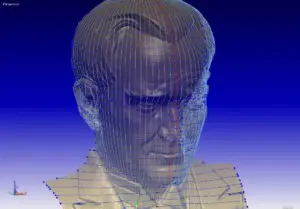

Picture 3 : STL data

Stage 2: The data required for both capturing the form and structural analysis are collected.

The measurements obtained as a result of optical scanning were enlarged for 4 m and 40 m models. Sections were created on the CAD data in radial and polar axes. These sections and joints were used both to define the form for the sculpture to be made by creating a network structure and to design the outline of the carcass structure to be used inside. Technical drawings and all necessary measurements of these sections were prepared and taken as reference data for the sculpture(s) to be made. When the production started in the basic dimensions of the building, where only the mask length was planned to be 40 meters, cross-sectional profiles were prepared at 1 meter intervals in order not to deviate from the accepted design and to make it exactly similar to the Atatürk model. These sections were taken as gauges and the profiles used in the main structures were produced according to these gauges.

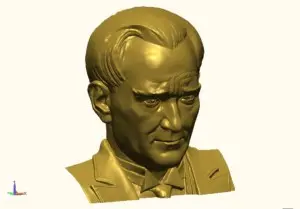

Picture 4: Network structure created on CAD data

The resulting network structure has been prepared to be used both in defining the form on a large scale and in the static analysis of the carcass structure to be used in it. Dear Prof. Dr. By Hikmet Aydin; The material, profile type, thickness, and carrier system design to be used in the sculpture, whose structural tests were carried out, were calculated using this network structure.

Stage 3: Determining the location of the new model with the hill data and creating the hill layout plan.

During the creation of the mud model, measurements were taken regarding the location where the statue would be placed. These measurements were data taken with a laser pointer from the slope from the base of the statue to the top. These data from the ground where the pedestal will sit and between the peaks are combined with the data obtained from the mud model. The most suitable place on the base floor has been determined.

According to these data, the portrait part that will form the main figure was positioned to scale, taking into account the base at the bottom and the total height.

The 4th stage is the integration of natural rock views and the surroundings of the sculpture in harmony with the environment.

The distance between the statue and the hill behind it must be completed both statically and visually and integrated with the environment in which it is located. For this purpose, natural rocks were added to the existing model by making another sculptural work to fill the gaps. This model was also dimensioned and transferred to the computer environment. With this preliminary study, it was tried to foresee how natural rocks can be used in the space and what construction needs to be done to associate them with the hill.

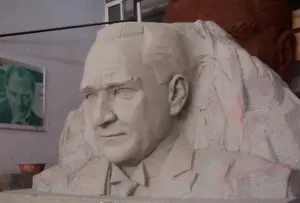

Picture 5: Natural Rock addition work

This mask, whose construction was completed in Çaldıran District of İzmir Buca Municipality, arouses the admiration of those who see it with its great magnificence. In order to understand the size of the work from the photographs, you can see people with an average height of 1.75m standing next to the Ataturk Mask in picture no. 15. In this form, the work has been applied to be registered in the Guinness World Records as the largest mask.

As Defne Engineering, we are proud to be able to contribute to this study. This statue, built in memory of the great leader Atatürk, will continue to be a source of pride for both your company and our country.

regards