Defne Muhendislik Ltd Sti. is established in 2005 to provide services for engineering projects such as reverse engineering, product design , 3-dimensional optical scanning, quality control and prototyping . Since its foundation providing engineering services to the key industry or subsidiary industries of the automotive, defense industry , white appliances and similar sectors. This paper is about creating a replica of Siloam Inscription projects.

Defne Muhendislik provides services only on project basis to all the sectors who are into product development and/or improvement. Although they are able to do their own design , prototype or reverse engineering tasks, firms need this kind of supports because of project schedule and workload .They can get this kind of support only from a company which is the expert in its field.

Defne Muhendislik is expanding the works about 3-dimensional scanning , reverse engineering , product design with its experienced engineer by using 2 Breuckmann Opto-Top HE system, Rapidform, CATIA and Top Solid software. Differently from other works Defne Muhendislik, benefited from the gained experiences , carried out precision works in archaeology area.

Considering delicate and brittle nature of the historical artifacts reproducing or getting a replica is not possible for every artifact. The Classical method of getting a silicon mold can damage the artifacts and prevents obtaining the desired precision and details because of the unavoidable air bubbles and chemicals reactions. We were able to achieve perfect results without touching the artifact by using a Breuckmann System. Our gained experience and equipment was enabled us to carry out the measurements for the replica of the SILOAM inscription.

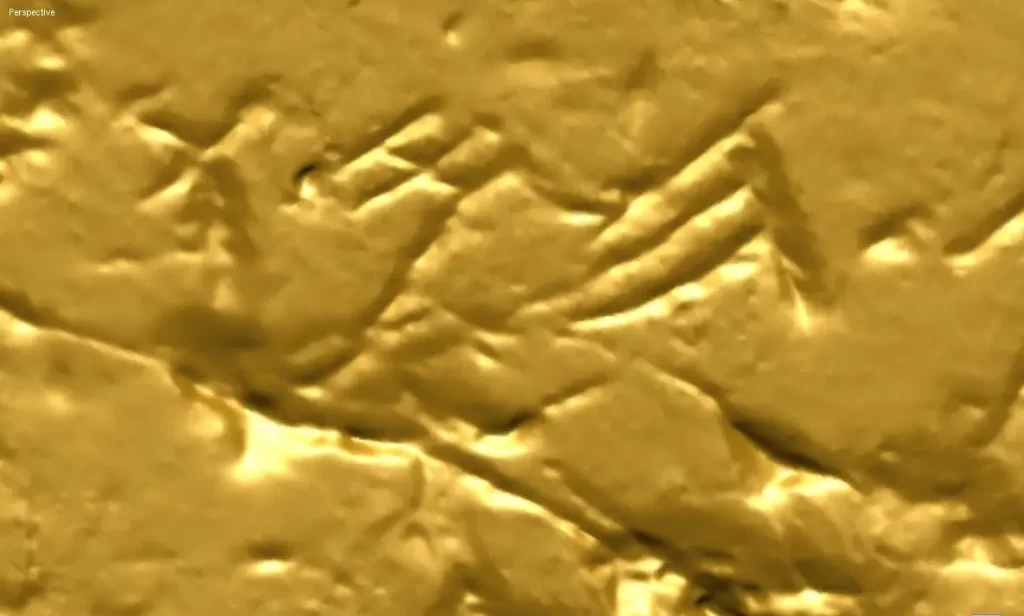

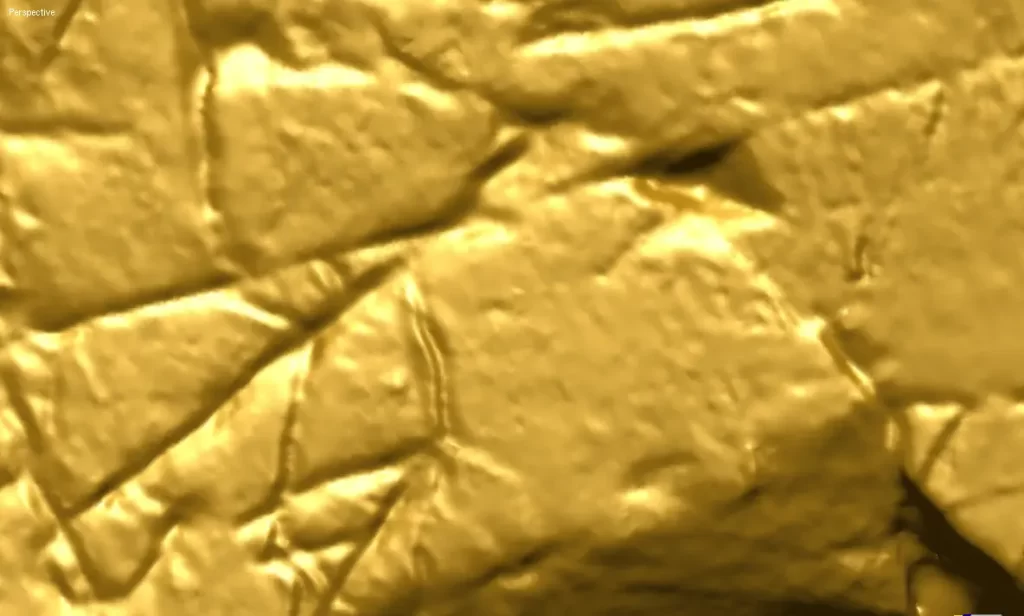

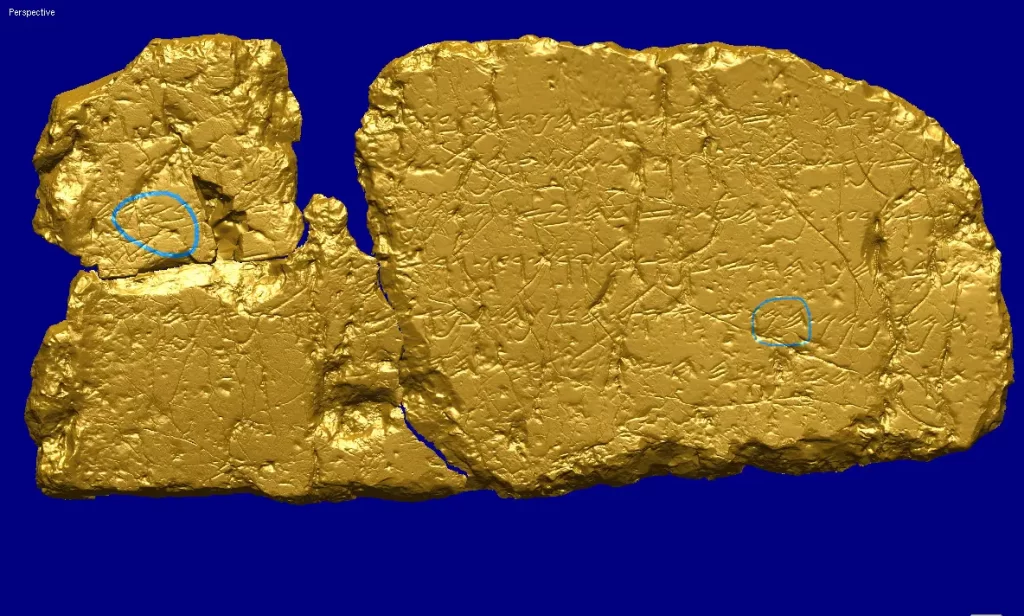

Siloam inscription was measured with Breuckman Opto_Top HE optic System. Acquired point cloud prepared as polygon data and processed for machinability to run with CNC. Appropriate lens configuration and system software parameters settings are made for sticking to authentic SILOAM inscription and transferring the time-related abrasion and the natural texture on the artifact into the computer setting. Measurements, transferred into the computer, had to be processed without converting to any other format. Post processing was done only by sticking to the raw data because conversion of data and the surface formation would lead to the details to be lost. After this stage CAM data was prepared from the point cloud to generate tool path .

During the CNC operations, high-speed cutting is performed with as small as possible diameter tools in order to bring out the details of the artifact on to the material of the model. After 144 hours CNC operations , processed model was containing not only the natural information but also all the details of the SLOAM inscription.

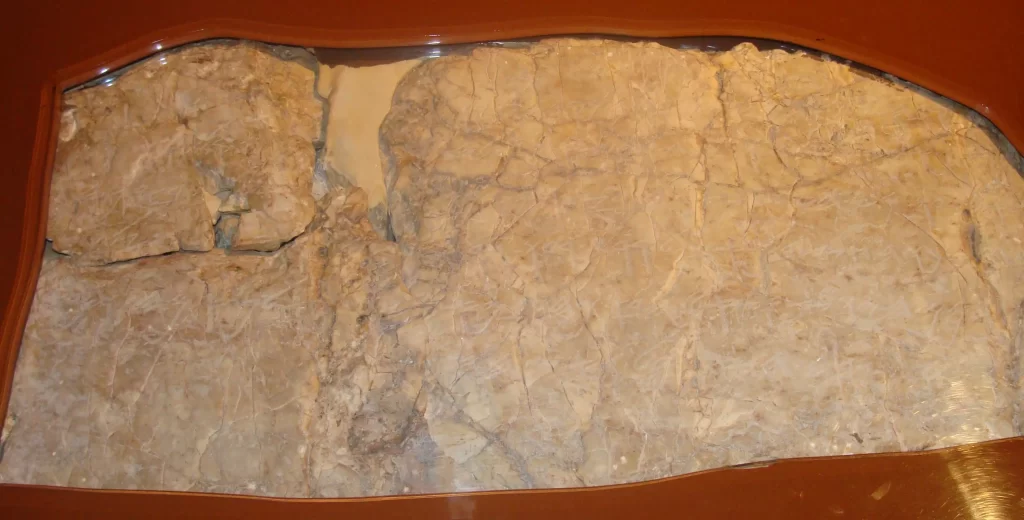

After the process of transferring the inscription on to the model , colour and pattern works are done by sticking to original artifact . In this pattern work super thin and strong paint is used so that paint does not cover all the details but at the same time it can provide necessary colour .

As a result of working with the excitement of measuring 2700 yers old historical artifact and the pride of adding positive value to the history, we achieved high customer satisfaction.

This artifact which belongs to our country will not be exposed to the risks anymore such as travelling long distances for exhibitions.